Description

Product Information:

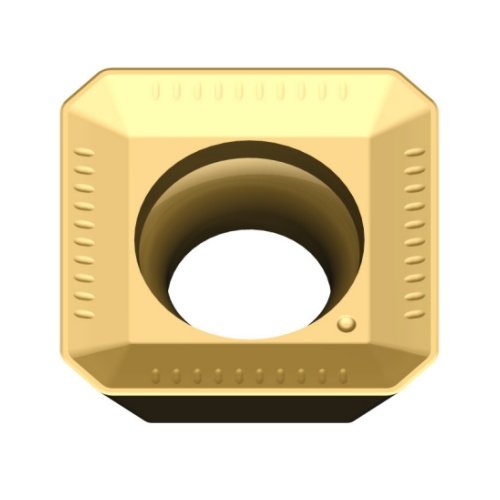

The SEER1203 face milling insert delivers high-precision metal cutting with excellent durability and smooth surface finishing. Designed with a square shape and 20° clearance angle, it provides stable performance, low cutting resistance, and extended tool life. Ideal for steel, stainless steel, and cast iron machining, this carbide insert ensures efficient material removal and consistent reliability for CNC milling applications.

Product Details:

Ultra-Sharp Precision-Ground Cutting Edge: The insert features a fully precision-ground cutting edge, providing exceptional sharpness and extremely low cutting resistance. This design is ideal for aluminum and non-ferrous materials, enabling smooth cutting, reduced tool vibration, and superior surface finish.

DLC / TiB₂ / PVD High-Performance Coating Options: Depending on machining requirements, the insert is available with advanced coatings such as DLC or TiB₂. These coatings provide a smooth, low-friction surface, excellent anti-adhesion characteristics, and increased wear resistance—ideal for high-speed machining of aluminum.

High Dimensional Accuracy and Stable Positioning: The insert’s seating surfaces and edges are precisely ground to ensure accurate positioning in the cutter body. This enables consistent performance during edge indexing and reduces machine setup time.

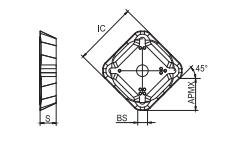

Main technical parameters:

| Length | Size (mm) | |||

| BS | APMX | I.C | S | |

| 12 | 1.5 | 6.5 | 12.7 | 3.19 |

| 15 | 2 | 8.5 | 15.875 | 4.76 |

| Type | ap (mm) | f (mm/rev) |

| SEER1203 | 1.50-6.00 | 0.10-0.25 |

| SEER1504 | 1.50-8.00 | 0.10-0.25 |

Reviews

There are no reviews yet.