Description

Introduction:

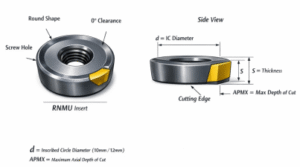

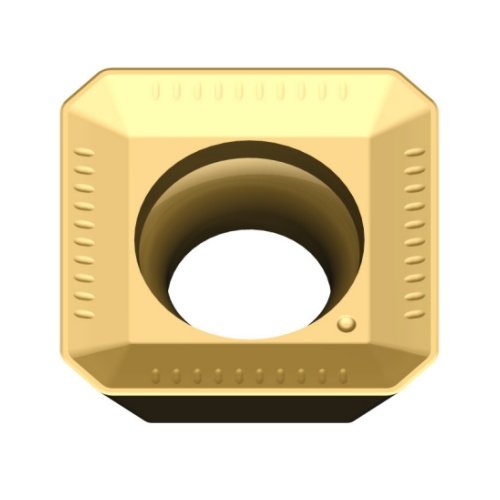

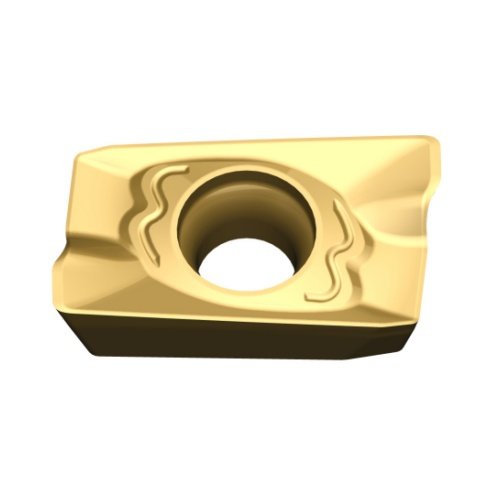

The Insert is engineered for advanced precision metalworking and high-efficiency machining operations. Featuring optimized geometry and robust carbide construction, these milling tools provide exceptional cutting stability, reduced vibration, and superior surface finish. The RNMU Insert is specifically designed to handle a wide range of materials, including hardened steels, aluminum alloys, titanium, and other high-strength metals, while maintaining consistent dimensional accuracy. Their three-flute design balances material removal rate and feed performance, enabling high-speed milling with minimized tool wear. Ideal for CNC machining centers, industrial fabrication, and complex milling tasks, these cutters extend tool life and enhance overall productivity. With excellent thermal and mechanical resistance, the RNMU10 APMX5.0 and RNMU12 APMX3.0 deliver reliable performance under demanding industrial conditions, making them an optimal choice for professional workshops and precision manufacturing environments.

Carbide Substrate Grade – High Toughness

Premium carbide substrate with enhanced toughness to resist chipping in interrupted cuts.

Multi-Layer PVD Coating – Wear Resistance

Multi-layer PVD coating (e.g., TiAlN + AlCrN) to improve wear resistance and thermal stability.

Helical Cutting Edge Geometry

Optimized helical cutting edge for smooth chip evacuation and reduced cutting forces.

Positive Rake Angle for Reduced Cutting Force

Positive rake angle to decrease cutting resistance and improve surface finish.

Corner Radius Options

Available corner radii to balance edge strength and surface quality requirements.

Coolant Through Capability

Coolant-through options to deliver cutting fluid directly to the cutting zone for heat control.

Precision Ground Shank

Precision ground shank ensures high concentricity and minimal runout.

Chip Breaker Geometry

Special chip breaker design to promote short, controlled chips in various materials.

High-Speed Cutting Capability

Designed for high surface speed operations with minimal vibration at elevated RPM.

Application Material Range

Suitable for a wide range of materials, including steels, stainless steels, titanium alloys, and high-temp alloys.

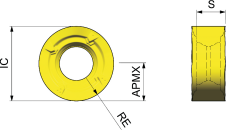

Main technical parameters:

| Type | IC | S | BS |

APMX |

| RN_10T3_ | 10.00 | 3.93 | – |

5.00 |

| RN_1204_ | 12.00 | 4.75 | – |

3.00 |

|

Type |

RE | Cutting Parameters | |

|

ap(mm) |

fz(mm/z) |

||

| RNMU10T3M04-WM | 5.0 | 0.60-5.00 |

0.12-0.39 |

| RNMU1204M06-WM | 6.0 | 0.80-3.00 |

0.14-0.42 |

Reviews

There are no reviews yet.