Description

Product Information:

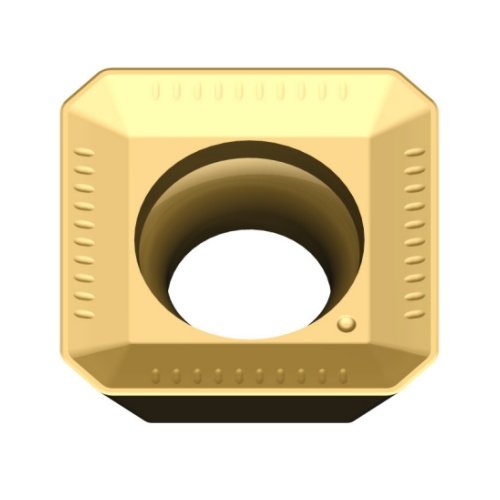

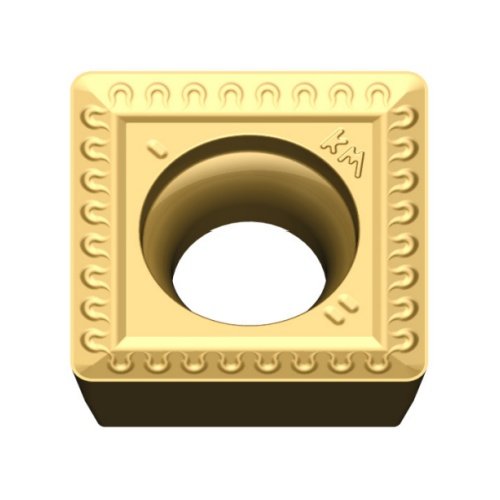

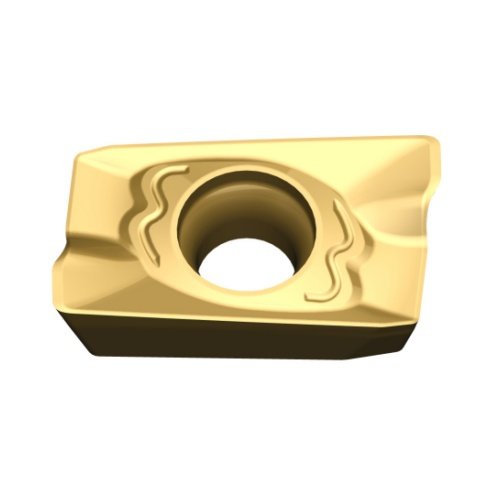

Designed for high-precision face machining, the face milling inserts feature an ultrafine-grain cemented carbide substrate and TiAlN composite coating (temperature resistance ≥800℃), with hardness over HRC65 for balanced wear and impact resistance. The unique square indexable structure + 4 effective cutting edges increases insert utilization by 50%, while the optimized cutting edge angle (12° rake angle) reduces cutting force and accelerates chip evacuation to avoid chip accumulation. Suitable for materials such as stainless steel (304/316), carbon steel (45#/Q235), and cast iron (HT200), it achieves surface roughness of Ra1.6-3.2, supports a cutting depth of 2-6mm, and is compatible with vertical machining centers and CNC milling machines.

Product Details:

The face milling insert is a high-performance tool for precision face machining, blending durability, efficiency, and versatility.

Made from ultrafine-grain cemented carbide (HRC 65+) with a TiAlN PVD coating (800℃ heat resistance, ≥50N adhesion), it resists wear/oxidation and lasts 40% longer than standard alternatives.

Main structures:

Reviews

There are no reviews yet.