Description

Introduction:

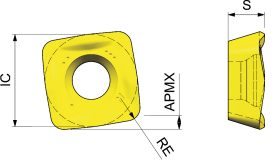

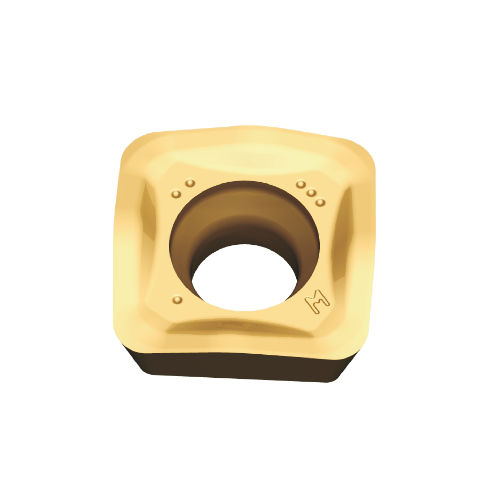

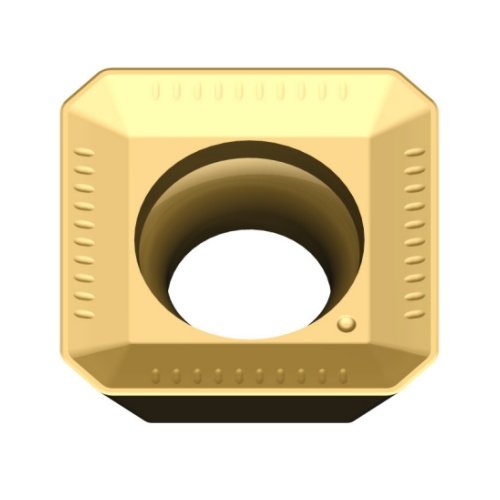

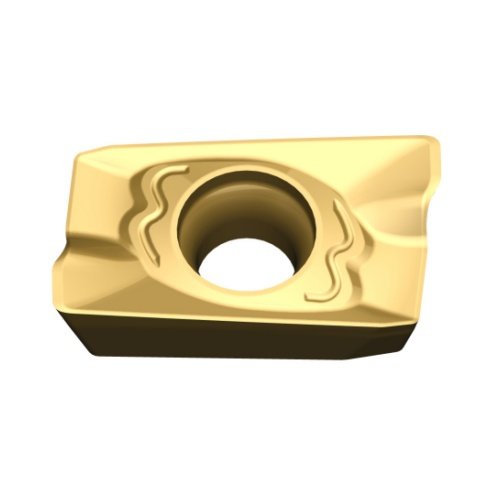

High Feed Milling Inserts – SOMT 09 APMX1.2 & SOMT 12 APMX2.1. Designed for precision high-feed milling, these carbide inserts feature optimized rake angles, reinforced edges, and advanced chipbreaker geometries to maximize metal removal rates while minimizing cutting forces. The multi-layer coating ensures excellent thermal stability, reduced adhesion, and extended tool life in demanding operations. Ideal for a wide range of materials, including alloyed steels (≤45 HRC), stainless steels, and cast irons.The insert excels in applications requiring high dimensional accuracy, vibration damping, and minimal tool wear, making them indispensable for precision components, mold and die machining, and high-efficiency industrial milling.

- Design

Optimized geometry for high-feed milling: stable performance, reduced vibration, and precise slot machining.

Rake and relief angles designed for superior chip control and edge strength.

Difference

SOMT 09: compact design for narrow slots and small-depth machining.

SOMT 12: larger insert and stronger edge for deeper cuts and heavy load machining.

- Development

Developed for milling steels, stainless steels, and cast irons with high efficiency.

Designed to extend tool life under both light and heavy cutting conditions.

Difference

SOMT 09: ideal for light machining and intermittent cuts.

SOMT 12: suitable for medium to heavy machining with enhanced corner strength.

- Technology

Advanced chipbreaker design ensures smooth chip evacuation and low cutting forces.

Micro-grain carbide material provides high toughness and wear resistance.

Optional hybrid CVD/PVD coating enhances thermal stability.

- Surface

Multilayer coating reduces friction, improves surface finish, and extends tool life.

Tailored coatings for specific feed rates and cutting depths.

Difference

SOMT 09: focused on moderate speed and low depth applications.

SOMT 12: optimized for high-feed, heavy-load conditions.

Main technical parameters:

|

Type |

IC | S | BS | APMX |

|

SO_09T3_ |

9.525 | 3.97 | – |

1.20 |

| SO_1205_ | 12.70 | 5.56 | – |

2.10 |

|

Type |

RE | Cutting Parameters | |

|

ap(mm) |

fz(mm/z) |

||

|

SOMT09T312-WM |

1.2 | 0.30-1.00 |

0.30-0.70 |

| SOMT120512-WM | 1.2 | 0.30-1.80 |

0.30-0.80 |

Reviews

There are no reviews yet.