Description

Introduction:

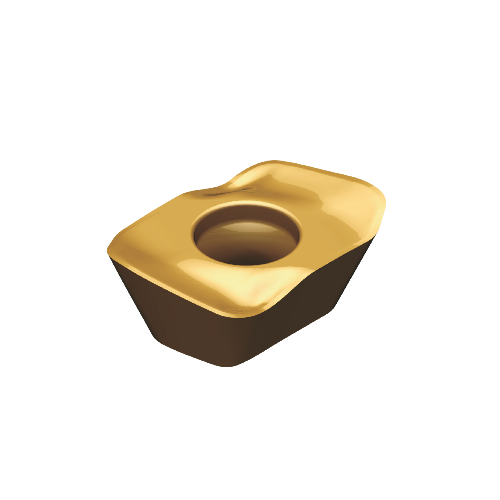

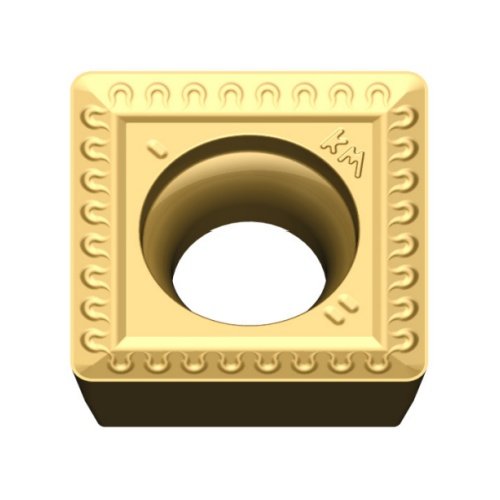

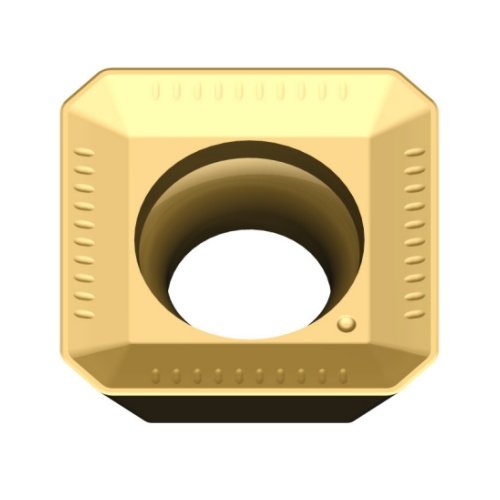

LO06 and LO08 profile milling inserts are designed for high-precision contouring and profiling operations in CNC machining. With optimized cutting geometry and reinforced edge design, these inserts ensure stable machining performance, excellent surface finish, and long tool life.

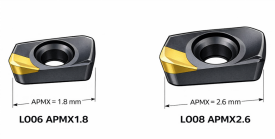

The LO06 insert features a maximum depth of cut (APMX) of 1.8mm, making it ideal for light to medium machining conditions that require high dimensional accuracy and smooth surface quality.

The LO08 insert offers a larger maximum depth of cut (APMX) of 2.6mm, supporting higher material removal rates under medium to heavy-duty cutting conditions while maintaining edge stability and wear resistance.

Manufactured from premium cemented carbide substrate combined with advanced wear-resistant coating technology, both models provide excellent thermal resistance, edge toughness, and reduced vibration during machining.

- Advanced Micro-Geometry for Stress Distribution

The insert feature engineered micro-geometry at the cutting edge that redistributes mechanical stress during milling, reducing localized stress concentration and minimizing micro-chipping. This enhances tool reliability under intermittent or complex contour loads.

- Coating & Carbide Synergy for Thermal Stability

The combination of ultra-fine carbide substrates and multi-layer PVD coatings creates a synergistic effect: high hardness at the cutting edge with thermal conductivity that dissipates heat efficiently. This prevents thermal softening and maintains dimensional accuracy at high cutting speeds.

- Optimized Chip Flow Channels

The chipbreaker geometry is tuned to create laminar chip flow, which reduces cutting force fluctuations and avoids built-up edge (BUE) formation. This lowers vibration amplitude and improves surface integrity on high-aspect-ratio profiles.

- Enhanced Edge Toughness via Grain Boundary Engineering

Microstructural control of the carbide grains at the edge increases fracture toughness, allowing the insert to withstand impact loads during entry, exit, or interrupted cuts without catastrophic chipping.

- Low-Force Milling through Optimized Rake and Relief Angles

Precise optimization of rake and relief angles reduces shear zone stress and cutting energy, resulting in lower spindle load and better energy efficiency, which is particularly critical for fine-profile LO06 inserts.

- Material Versatility from Thermo-Mechanical Balance

The combination of substrate toughness and coating hardness provides a thermo-mechanical balance that allows consistent cutting performance across steels, stainless steels, cast irons, and hardened alloys, even under varying temperatures.

- Vibration Damping and Process Stability

The insert geometry and material composition act as intrinsic vibration dampers. By reducing chatter tendency, they allow higher material removal rates while maintaining contour accuracy, critical for long-length or thin-wall profiles.

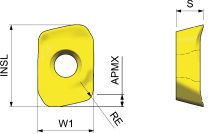

Main technical parameters:

| Type | INSL | W1 | S |

APMX |

| LO_0603_ | 9.40 | 6.25 | 3.40 |

1.80 |

| LO_0804_ | 12.00 | 8.25 | 4.00 |

2.60 |

|

Type |

RE |

Cutting Parameters |

|

| ap(mm) |

fz(mm/z) |

||

|

LOEX060320R-WL |

2.0 | 0.60-1.50 | 0.30-0.70 |

|

LOMX060320R-WL |

2.0 | 0.60-1.50 |

0.30-0.70 |

| LOEX080425R-WL | 2.5 | 0.80-2.30 |

0.30-0.80 |

| LOMX080425R-WL | 2.5 | 0.80-2.30 |

0.30-0.80 |

Reviews

There are no reviews yet.