Description

Introduction:

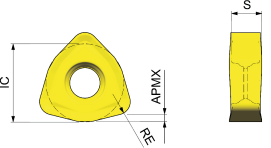

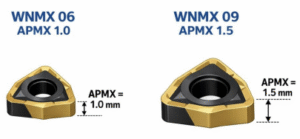

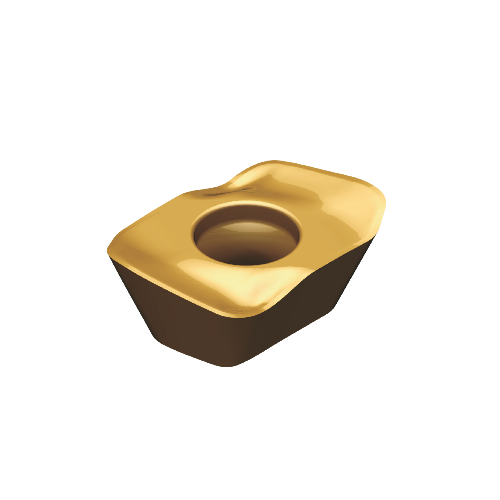

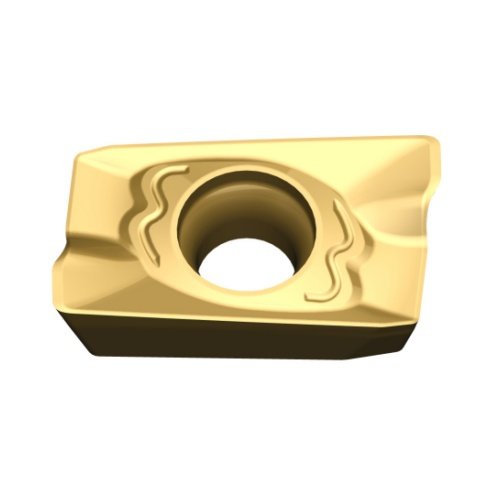

The High-Feed Milling Insert series, including WNMX 06 APMX1.0 and WNMX 09 APMX1.5, is designed for high-performance machining in demanding industrial applications. Engineered with advanced carbide substrates and state-of-the-art PVD (Physical Vapor Deposition) coatings, these inserts offer exceptional wear resistance, reduced friction, and enhanced thermal management, ensuring high cutting efficiency and extended tool life in high-speed, high-feed operations.

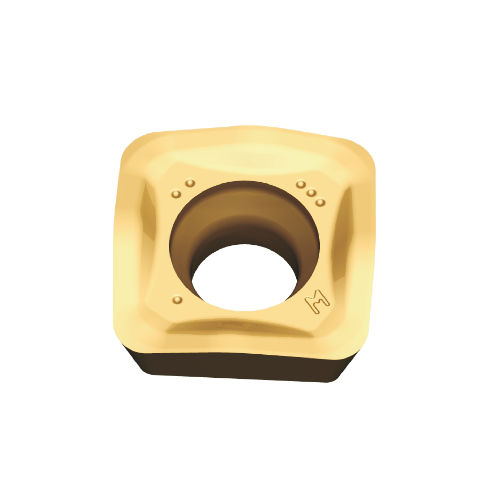

The APMX1.0 and APMX1.5 geometries are optimized for high chip removal rates while maintaining cutting edge stability, even in extreme machining conditions such as heavy depths of cut and high cutting speeds. The inserts’ unique geometry ensures effective chip flow and evacuation, minimizing the risk of built-up edge (BUE) formation, which leads to improved surface finishes and longer tool life.

By incorporating precisely engineered edge profiles and optimized rake angles, these inserts reduce cutting forces and minimize tool deflection and vibration, even at higher feed rates. This design enhances process stability and is ideal for machining hard-to-cut materials like high-alloy steels, stainless steels, and heat-resistant alloys.

The innovative coating technology provides a unique balance of hardness and toughness, allowing the inserts to withstand thermal shock and mechanical wear, even in aggressive machining conditions. This reduces downtime and improves overall productivity. Furthermore, the insert performs excellently on both conventional CNC machining centers and advanced multi-axis machines, making them suitable for aerospace, automotive, mold & die, and energy sectors where precision and productivity are essential.

Specialized Design

WNMX 06 APMX1.0 and WNMX 09 APMX1.5 inserts are specifically designed for high-feed milling operations, offering excellent chip removal rates while maintaining tool life.

Advanced Geometry

These inserts feature a unique geometry with a positive rake angle and optimized cutting edge design to reduce cutting forces and ensure smoother cuts.

Chip Control

High-feed inserts are engineered to efficiently evacuate chips, reducing the risk of built-up edge and preventing clogging, which ensures continuous and stable cutting performance.

Versatility

The WNMX 06 APMX1.0 is suitable for smaller workpieces and more intricate geometries, while the WNMX 09 APMX1.5 insert is designed for larger workpieces with higher depth of cut and feed rates.

Improved Surface Finish

These inserts deliver excellent surface finish due to their smooth cutting action, even when milling high-strength materials or tough alloys.

Durability and Consistency

Designed to provide consistent and reliable performance over extended periods, these inserts are ideal for high-volume production environments.

Cost-Efficiency

The high-feed design not only enhances productivity but also reduces machining costs by shortening cycle times and minimizing the need for frequent tool changes.

Main technical parameters:

|

Type |

IC | S | BS |

APMX |

| WN_0603_ | 6.00 | 3.18 | – |

1.00 |

| WN_09T3_ | 9.00 | 3.97 | – |

1.50 |

|

Type |

RE | Cutting Parameters | |

|

ap(mm) |

fz(mm/z) |

||

| WNMX060312ZNN-WL | 1.2 | 0.30-1.00 |

0.30-0.70 |

| WNMX09T316ZNN-WL | 1.6 | 0.30-1.50 |

0.30-0.80 |

Reviews

There are no reviews yet.