Description

Introduction:

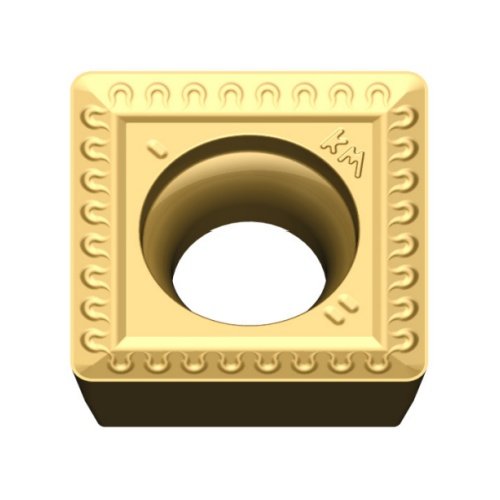

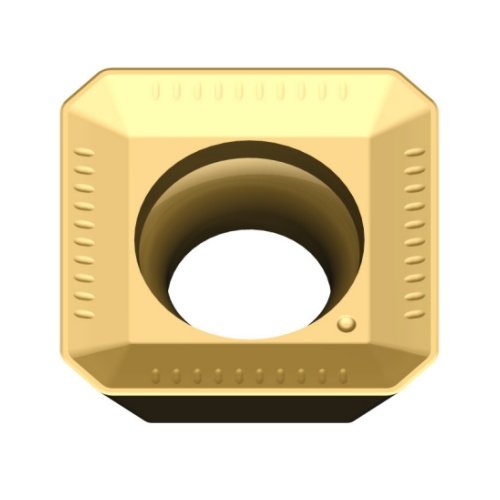

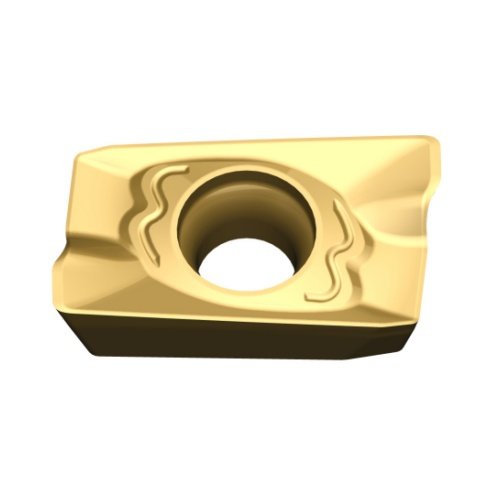

The helix milling insert features a unique helical edge design, combined with an ultrafine-grain cemented carbide substrate and TiAlN composite coating (temperature resistance ≥800℃). With hardness over HRC65, it balances impact resistance and wear resistance. The helical edge structure optimizes the cutting path, reducing cutting force while accelerating chip evacuation to avoid chip clogging. It is suitable for face milling and step milling of materials such as stainless steel (304/316), carbon steel (45#), and cast iron (HT200). Supporting a cutting depth of 2-8mm and surface roughness of Ra1.6-3.2, it is compatible with vertical machining centers and CNC milling machines. Direct supply from the manufacturer with customizable AlCrN high-temperature coating to meet mass machining needs in construction machinery and auto parts industries.

Product Details:

- Made from 100% raw tungsten carbide material

- Produced with German machine and Japen coating machine

- All products go through in-process and 3 times inspection

Main structures:

Reviews

There are no reviews yet.