Description

Product Information:

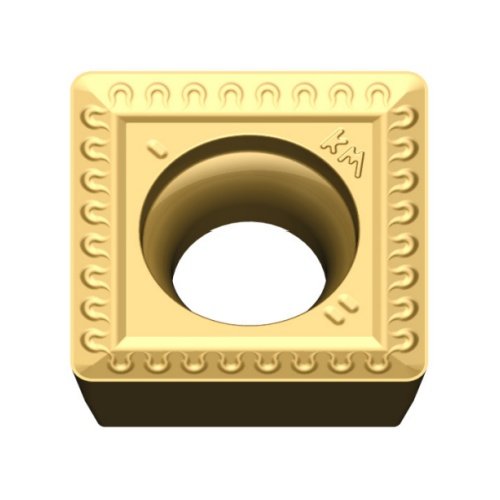

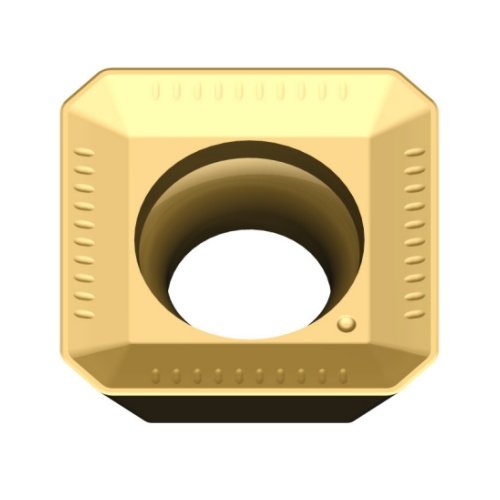

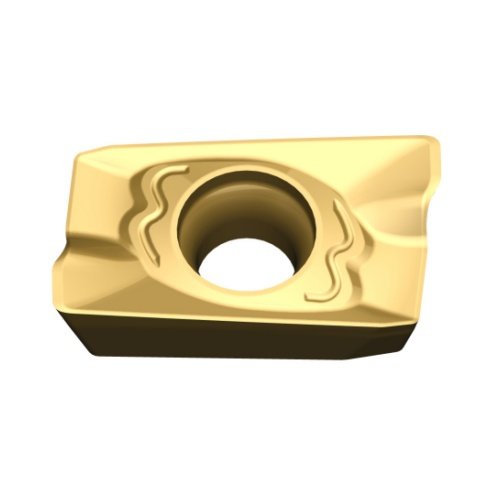

Designed for high-load rapid cutting, the high-feed milling insert features an ultrafine-grain cemented carbide substrate and TiAlN composite coating (temperature resistance ≥800℃), with hardness over HRC65 for excellent impact and wear resistance. Its unique regular hexagonal structure + multi-flute design increases feed rate by 50% compared to conventional milling inserts, suitable for rough/semi-finish milling of difficult-to-machine materials such as stainless steel, superalloys, and high-strength steel. It supports a cutting depth of 1-5mm with surface roughness Ra3.2, compatible with vertical machining centers and CNC milling machines. Direct supply from the manufacturer with customizable coatings (e.g., AlCrN) to meet high-efficiency machining needs in construction machinery and aerospace fields.

Product Details:

Coating: Ultra-fine grain coating technology provides better wear resistance and toughness.

Substrate: inserts shows a good capability against plastic deformation and good capability of red hardness.

Application fields: Precise mould,automobile,aerospace,rail.

Scope: Cemented carbide inserts for turning,milling,grooving,drilling, and aluminium machining.

Main structures:

Reviews

There are no reviews yet.