Description

Product Information:

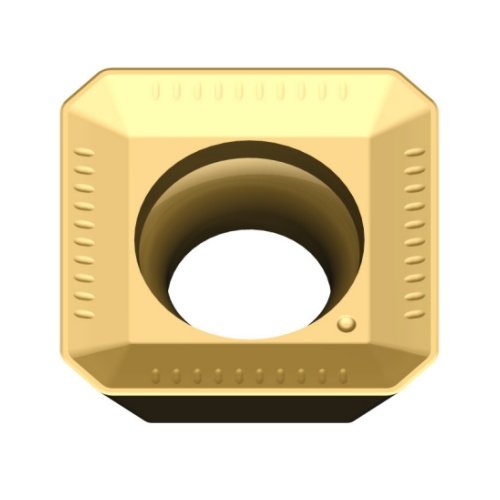

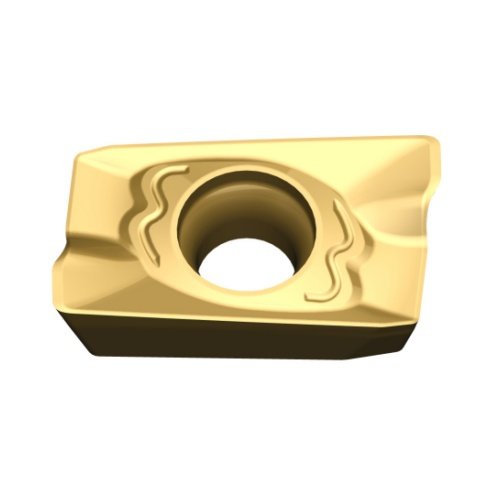

The profiling milling insert is made of ultrafine-grain cemented carbide substrate with TiAlN composite coating, featuring hardness up to HRC65+ and excellent impact resistance & wear resistance. It is suitable for complex contour profiling milling of materials like stainless steel, carbon steel, and cast iron. With 0.8mm nose radius and 3.97mm insert thickness design, it ensures curved surface machining precision (IT8 grade) and surface roughness Ra1.6, compatible with CNC milling machines and machining centers. Direct supply from the manufacturer supports bulk customization to meet the profiling milling needs of mold cavities and box parts.

Product Details:

Industrial-grade profiling milling insert optimizes the cutting edge angle for complex curved surface milling, reducing cutting resistance and vibration risk, suitable for deep cavity and special-shaped contour machining. Precision grinding through the entire process ensures dimensional tolerance of ±0.01mm, enabling stable processing consistency in multiple batches.

Main structures:

Reviews

There are no reviews yet.