Description

Introduction:

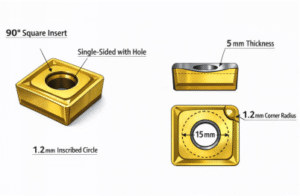

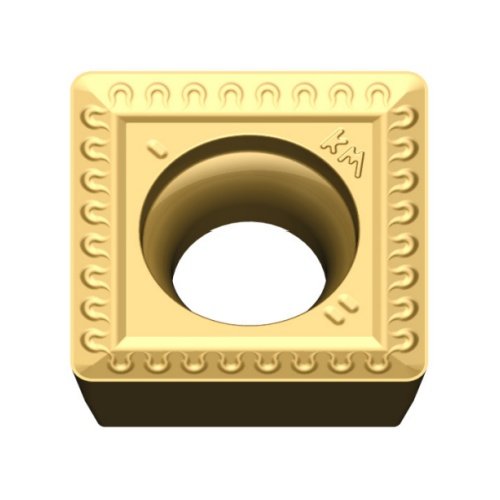

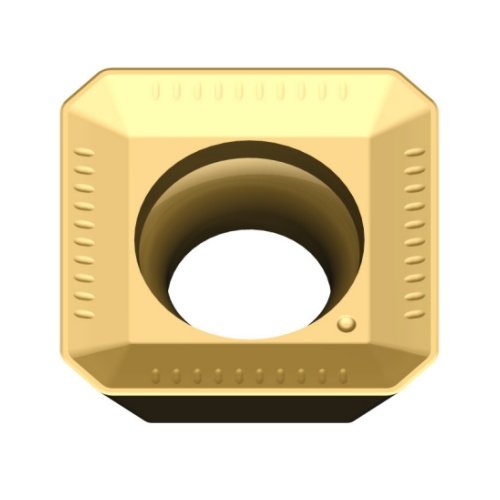

The SDMT150512 high-feed milling insert is designed for high-speed and high-feed machining applications. With optimized cutting geometry and reinforced cutting edges, this carbide insert ensures low cutting resistance, stable performance, and excellent chip evacuation.

Manufactured from high-quality tungsten carbide substrate and coated with advanced PVD/CVD technology, the insert delivers superior wear resistance, heat resistance, and long tool life under demanding machining conditions.

This High-Feed Milling Insert is suitable for:

Alloy steel milling

Stainless steel machining

Cast iron cutting

Mold and die machining

Automotive component production

The double-sided design increases cost efficiency and maximizes productivity, making it an ideal solution for roughing and semi-finishing operations.

- Low Entering Angle Geometry

The insert utilizes a small entering angle (typically 10°-17°), transforming radial cutting forces into axial forces. This significantly reduces vibration and improves machining stability, especially on long overhang tools and less rigid setups.

- High Feed Capability with Chip Thinning Effect

The chip thinning principle allows feed rates 2-4 times higher than conventional 90° milling insert while maintaining controlled chip thickness. This increases productivity without increasing cutting depth.

- Reinforced Cutting Edge Preparation

Special edge honing or chamfering strengthens the cutting edge, improving resistance to chipping and ensuring reliable performance under high feed and heavy load conditions.

- Advanced Coating Technology

Available with high-performance PVD/CVD coatings such as TiAlN or AlTiN, providing excellent wear resistance, thermal stability, and oxidation resistance for high-speed machining applications.

- Optimized Carbide Substrate

Fine-grain carbide substrate ensures an ideal balance between hardness and toughness, offering outstanding resistance to thermal cracking and plastic deformation.

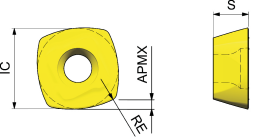

Main technical parameters:

| Type | IC | S | BS |

APMX |

| SD_1205_ | 12.70 | 5.56 | – |

1.50 |

| SD_1505_ | 15.875 | 5.56 | – |

1.90 |

|

Type |

RE | Cutting Parameters | |

|

ap(mm) |

fz(mm/z) |

||

|

SDMT120512-WM |

1.2 | 0.30-1.30 | 0.30-0.70 |

|

SDMT150512-WM |

1.2 | 0.40-1.70 |

0.30-0.80 |

| SDMT120512-WH | 1.2 | 0.30-1.30 |

0.30-0.70 |

| SDMT150512-WH | 1.2 | 0.40-1.70 |

0.30-0.80 |

Reviews

There are no reviews yet.